BLISSart Powerfilter

BLISSart inside tube scarfing systems are exposed to contamination during daily operation. In most operations the impeder as well as the planing tool are being cooled with emulsion, which, even after filtering, contains enough small particles to clog the cooling channels. Our BLISSart-Powerfilter Station guarantees the uninterrupted operation of our inside tube scarfing systems.

The BLISSart-Powerfilter consists of two separate filter systems with a switching valve to toggle between the two. This makes quick filter exchanges possible without having to interrupt operations.

A pressure gauge constantly shows the current operating pressure to ensure that the system is always being operated at optimum working pressure. The electronic flow switch immediately sends a signal when the filter is clogged and needs to be exchanged.

The complete filter system is mounted on a baseplate and can thus easily be mounted on the welding line. The exchangeable filter is made of a heavy-duty special fabric and has a filter surface of 140.000 mm² per filter. We offer filter strengths of 5 to 100 µ. Our standard filter features a double filter bag that consists of an inner filter of 100 µ and an outer filter of 30 µ thickness, thus protecting the bag from mechanical damage. With our BLISSart-Powerfilter pressure loss in a 5-bar-cooling liquid pump is only about 0.1 bar.

06.2020

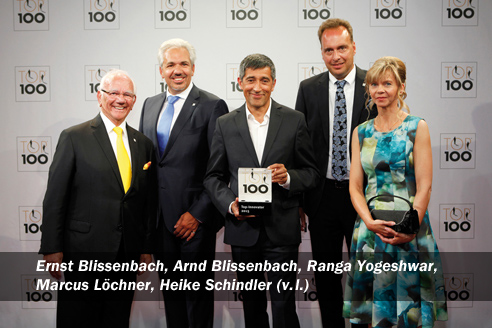

Ernst Blissenbach zum Innovations-Champion gekürt

Überlingen / Remscheid – Altes loslassen und Neues wagen: Als innovativer Mittelständler darf man keine Angst vor dem Wandel haben, sondern muss ihn als Chance begreifen. Bei der 27. Runde des Innovationswettbewerbs TOP 100 überzeugte die Ernst Blissenbach GmbH aus Remscheid erneut. Im wissenschaftlichen Auswahlverfahren beeindruckte man wieder in der Klasse bis 50 Mitarbeiter – besonders in den Kategorien „Innovationsklima“ sowie „Innovationsförderndes Top-Management“. Damit gehört das Unternehmen ab dem 19. Juni 2020 nunmehr bereits zum vierten Mal zu den Top-Innovatoren in Deutschland.

Firmenchef und Eigentümer Ernst Blissenbach ist nicht nur seit vielen Jahren Fan des FC Bayern München – er nimmt sich den deutschen Spitzenclub und seinen Ex-Boss Uli Hoeneß auch gerne als Vorbild. „Wer mehr erreichen will als Durchschnitt, muss auch bereit sein, mehr zu geben als Durchschnitt“ ist dabei seine logische Maxime. „Wir wollen wie die Bayern qualitativ zur absoluten Spitzenklasse gehören – da muss man sich schon ordentlich ins Zeug legen. Mit dieser Einstellung hat Ernst Blissenbach seine Firma aus dem Bergischen Land nicht nur in den TOP 100 der innovativsten deutschen Unternehmen platziert, sondern auch an die Weltspitze der Werkzeughersteller für die Innenentgratung längsnahtgeschweißter Rohre geführt. Der bei dieser Rohrfertigung im Inneren entstehende Grat muss entfernt werden, um Bruchstellen zu verhindern und Maschinenstillstände oder Ausschussraten zu verringern. Mit den Systemen von Blissenbach werden Präzisionsstahlrohre für die Automobil-, Möbel- und Freizeitindustrie sowie für die Medizintechnik und die Elektromobilität produziert.

Nur eine optimal durchdachte Konstruktion sichert die Spitzenposition bei den Hightech-Werkzeugen. Eigeninitiativ eingebrachte Vorschläge sind beim viermaligen Top-Innovator ausdrücklich erwünscht. „Unsere Mitarbeiter haben keine Scheu, Verbesserungsvorschläge zu machen.“, sagt Ernst Blissenbach und fügt lächelnd hinzu, „Was mit einer Belohnung natürlich noch mehr Spaß macht.“ In Innovation-Labs können Mitarbeiter und Kunden ihre Ideen austauschen. „Die Belegschaft ist die Basis für unsere enorme Innovationskraft. Wissen, Qualität und Bereitschaft treffen hier auf Können, Wollen und Dürfen“, resümiert Blissenbach und betont, dass der Kundennutzen dabei immer im Vordergrund steht: „Ein Kunde aus Portugal konnte beispielsweise dank unserer Produkte mehr als € 100.000,-- an Stromkosten einsparen.“

„Top 100“: der Wettbewerb

Seit 1993 vergibt compamedia das TOP 100-Siegel für besondere Innovationskraft und überdurchschnittliche Innovationserfolge an mittelständische Unternehmen. Die wissenschaftliche Leitung liegt seit 2002 in den Händen von Prof. Dr. Nikolaus Franke. Franke ist Gründer und Vorstand des Instituts für Entrepreneurship und Innovation der Wirtschaftsuniversität Wien. Mentor von TOP 100 ist der Wissenschaftsjournalist Ranga Yogeshwar. Projektpartner sind die Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung und der BVMW. Als Medienpartner begleiten das manager magazin, impulse und W&V den Unternehmensvergleich. Mehr Infos unter www.top100.de.

07.2018

TOP 100

The TOP 100 contest will select the most innovative companies among Germany`s small and medium sized enterprises for the 25th time. This year Ernst Blissenbach GmbH is one of those innovation leaders. That is the result of an analysis undertaken by the Research Director of TOP 100, Prof. Dr. Nikolaus Franke. TOP 100`s men tor Ranga Yogeshwar will present the award to the company from Remscheid together with Franke and compamedia on June 29th, 2018 at the 5th German SME Summit in Ludwigsburg. For Ernst Blissenbach GmbH it is already the third time that they have made it into this elite group of innovators. In the independent selection process the company with 15 employees im-pressed the jury especially with its successful innovation and its excel-lent innovation climate.

The Top 100 competition

Since 1993, compamedia has been awarding the Top 100 seal of approval to SMEs with particular innovative capacity and above-average success rates for innovations. This project has been coordinated by Professor Nikolaus Franke from the Institute of Entrepreneurship and Innovation at the Vienna University of Economics and Business Administration since 2002. Professor Franke is one of the world’s leading experts in the field of user innovation. The Top 100 is mentored by journalist and television presenter Ranga Yogeshwar, and organised in partnership with the Fraunhofer Society for the Promotion of Applied Research. manager magazin provides media support for the company benchmarking competition. Further information is available at www.top100.de.

compamedia – mentor to Germany’s top SMEs

compamedia GmbH, which was founded in 1993 and employs 15 people, organises the nationwide company benchmarking competitions Top 100 (since 1993) and Top Consultant (since 2010). The company collaborates with prestigious universities on these projects.

04.2018

Best of IP 2018 for the fourth time

Ernst Blissenbach GmbH has received the coveted award “Best of IP 2018” for the fourth time. The publishing house Huber Verlag für Neue Medien is handing out the INDUSTRY AWARD to honor the best solutions in INTEGRATED INDUSTRY. www.industriepreis.de

02.2017

Won!

To the 3rd time Huber publishing company distinguished the expert's jury for Neue Medien GmbH the Ernst Blissenbach GmbH for an especially advanced manufactured product with a high technological, economic and ecological customer use. The predicate: Best of 2017.

With the ID Scarfing Systems Ernst Blissenbach GmbH is an international developer, manufacturer and world market leader of inside tube scarfing tools for longitudinally welded tubes. With these systems any production of longitundinally welded tubes becomes safer, easier, more environmentally compatible and more economical.

The independent professional jury consisting of industry-branch experts, professors and professional journalists form the select circle of the judges. They provide for maximum objectivity and make the price in the industrial branch so unique.

06.2017

Keep Things Flowing Smoothly

The future belongs to smart solutions; Ernst Blissenbach is convinced of it. That is also the reason why the entrepreneur is not worried: His smart solutions for inside tube scarfing of longitudinally welded tubes have already secured him a unique position in the world market. As far as technology is concerned his competition is lagging far behind – and is still working with technology which the Ernst Blissenbach GmbH used as early as just after the turn of the millennium.

Due to his energy, vision, and foresight Ernst Blissenbach was able to build an extremely successful company. His company manufactures specialty tools and is the undisputed world leader in its niche. But what exactly is the benefit of the solutions for inside tube scarfing developed by Blissenbach? Blissenbach likes to compare tube systems with human arteries. If they are calcified and cause bottlenecks the doctors sound the alarm. In the context of industry, it is very much the same thing: If tube systems do not guarantee an unobstructed flow, that creates a dangerous situation.

A Turbocharger for Production

The inside tube scarfer developed by Ernst Blissenbach solves this problem and delivers better production results and smoother operations. The company supplies its customers with particularly heat-resistant cutting rings and a diagnostic system, also called Seam Monitoring. That guarantees that even the smallest irregularities do not escape notice. The specialized tools made by Blissenbach are a real turbocharger for production: Less machine downtime and fewer failures make for a more efficient and cost-effective production. A customer in Portugal was able to reduce his electricity costs by more than 100.000 €.

Innovative Impact Protection

Technology made by Blissenbach saves lives every day: It took three years of development to design a special tool made of high-alloyed tool steel to provide inside scarfing for tubes able to withstand deformation at 4,000 bar. These tubes help better protect the passenger compartment of motor vehicles and provide a smart solution for optimizing the side impact protection component – one that can only come from Blissenbach. After all, this company has a technological head-start of about 15 years over the competition.

The Top 100 competition

Since 1993, compamedia has been awarding the Top 100 seal of approval to SMEs with particular innovative capacity and above-average success rates for innovations. This project has been coordinated by Professor Nikolaus Franke from the Institute of Entrepreneurship and Innovation at the Vienna University of Economics and Business Administration since 2002. Professor Franke is one of the world’s leading experts in the field of user innovation. The Top 100 is mentored by journalist and television presenter Ranga Yogeshwar, and organised in partnership with the Fraunhofer Society for the Promotion of Applied Research. manager magazin provides media support for the company benchmarking competition. Further information is available at www.top100.de.

compamedia – mentor to Germany’s top SMEs

compamedia GmbH, which was founded in 1993 and employs 15 people, organises the nationwide company benchmarking competitions Top 100 (since 1993) and Top Consultant (since 2010). The company collaborates with prestigious universities on these projects.

11.2016 | Source: Remscheider General-Anzeiger

Ernst Blissenbach Company Receives Innovation Award

This afternoon the Remscheid-based Ernst Blissenbach Company received the ‟Reinhard and Max Mannesmann Innovation Award 2016” at the German Tool Museum located in Cleffstraße in Remscheid-Hasten. ‟The award ceremony is one of the highlights of our association work. Additionally it provides the appropriate setting”, Professor Dr. Horst A. Wessel, President of the Friends' Association Förderverein MannesmannHaus e.V. added, after he welcomed the owner and managing director Ernst Blissenbach as well as his family and senior employees of the company.

Mr. Blissenbach received the award for his development of a world market leading system for inside tube scarfing in the production of longitudinally welded pipes. ‟If you are now thinking: ‟Why would a Mannesmann organisation give an award to a competitor? ”, we managed to convince you today, that we enjoy a great deal of independence in our work”, Wessel said with a wink in his eyes. Today`s welded pipes are of such high quality, that it is difficult to prove the existence of a seam. Innovation is absolutely essential for survival and therefore creativity has to be nurtured and promoted. ‟If you want to secure the future, you have to invest in it”, Wessel added.

The title of his presentation was ‟The History of the Longitudinally Welded Steel Pipe and its Market Share in Comparison to the Pipe Invented in Remscheid” and highlighted the development of the various types of pipes including current electrical processes. His conclusion was: ‟The welded pipe has always given the seamless pipe a run for its money. The difference these days is so small that the price is generally the decisive factor. If this development continues the seamless pipe might disappear altogether one day”.

‟A lot of things that were conceived in Remscheid are produced somewhere else in the world” Burkhard Mast-Weisz, Lord Mayor of Remscheid proudly added and expressed the hope that Remscheid`s economy and climate of innovation would produce ‟many more young recipients of the Mannesmann award”.

According to Karl Rudolf Gerhards, Chairman of the Board of the Friends' Association, the Blissenbach company emerged victorious from a pool of 20 competitors because of their impressive development of tools for inside tube scarfing, the invention of patented monitoring systems, the ascent to technology and world market leadership, and continued development, which in this case is based on cooperation. ‟Innovation-driven performance is the engine that powers the economy and society. That is true for Mannesmann as well as the Ernst Blissenbach GmbH”.

The Recipient of the Award Delivered an Emotional Speech

The Lord Mayor presented the certificate and Wessel presented the commemorative medal to the visibly moved honoree, who thanked the jury for the award, but most of all he thanked his employees: ‟I extend my heartfelt thanks to all of the employees, because their wealth of ideas is the basis for the company`s success and the numerous new products. I would not be here today without them. That is why I dedicate this award to the whole team”. Ernst Blissenbach reminisced about the 70s and his first contacts with the Mannesmann company. There were been failures and setbacks, but today world market leadership is a reality for this system. ‟We have an export rate of 80 percent”. Since today innovations are more important than ever, every employee is given his own space in his company, and that is appreciated. ‟That is certainly the case for my son and our highly qualified employees”, Ernst Blissenbach said in conclusion of his emotional speech.

In 2011 the company received the ‟Industry Award for Innovative Products” – an initiative of German Small and Medium Sized Enterprises. Last year Ernst Blissenbach GmbH was awarded the Top-100-Award from the Vienna University for Economics and Business Administration.

Today`s award was created in memory of the Mannesmann Group and especially the two ingenious inventors Reinhard and Max Mannesmann. The two inventors as well as the company have always stood for extensive innovative achievements. FOUNDING OF THE COMPANY More than 110 years ago the company emerged as a pipe rolling mill from a high quality file factory which had won multiple awards and had its own steel production in Remscheid. It developed into a worldwide technology corporation with headquarters in Düsseldorf.

‟So Mannesmann is where it all started. That is a consolation since we are giving this award to the killer of the seamless pipe”, Wessel joked, receiving spontaneous applause from the guests.

07.2015

Outstandingly innovative:

Ernst Blissenbach GmbH

Ernst Blissenbach is one of Germany’s most innovative SMEs / Presentation of award by Ranga Yogeshwar.

Remscheid – Success built upon entrepreneurial vision: Ernst Blissenbach GmbH is honoured as one of Germany’s most innovative SMEs at the German SME Summit in Essen on 26 June. The Remscheid-based company joins an exclusive group of prizewinners stretching back over more than 20 years as Top 100 mentor Ranga Yogeshwar awards it the Top 100 seal of approval. The award to Ernst Blissenbach is the out-come of a two-stage analytical procedure by a team of research scien-tists.

Ernst Blissenbach GmbH’s innovations are setting standards worldwide. The Remscheid-based company develops systems which enable pipes to be produced with particularly smooth internal surfaces, whilst offering maximum reliability for demanding pipe production processes. The company’s innova-tive lead over the rest of the field is huge – an impressive 15 years ahead of both national and international competitors.

Ernst Blissenbach scored particularly well in the Top 100 competition’s Innovations Marketing category. Its engineers work together with customers to develop tangible solutions, and exchange ideas and information on best practice in joint workshops. This enables the company to check at an early stage whether its innovation projects are feasible and to react swiftly to the needs of the market. Plenty of inspiration for new products also comes from within the company. Managing director Ernst Blissenbach encourages his 15 employees always to think outside the box and places particular emphasis on a no-blame culture. As a result, there is a constant stream of innovative products.

“Generating good ideas and implementing them quickly is an important competitive factor for us,” commented Blissenbach. “This is why we invest a lot of time and money into managing innovation. In doing so, we are relying on the creativity and inventiveness of all of our employees. I should like to extend my heartfelt thanks to them for helping us win this Top 100 award.”

The Top 100 accolade is awarded on the basis of a two-stage analysis de-veloped by Nikolaus Franke, Professor of Entrepreneurship and Innovation at the Vienna University of Economics and Business Administration, and his team. The research scientists use more than 100 parameters in five separate categories to investigate how SMEs manage and generate successful innovations. The decision as to which companies ultimately receive the Top 100 award lies exclusively with the academic coordinators of the project.

This year, Professor Franke and his team reviewed more applicants than ever before, with 234 out of a total of 302 qualifying companies making it into the final. After the finalists had been split into three size categories (maximum of 100 companies in each size category), 178 were awarded the accolade. The German SME summit in Essen provided the setting for the awards ceremony.

The Top 100 are outstanding in every respect: this year’s crop includes 71 domestic market leaders and as many as 31 global market leaders. In the last three years, the top innovators have together applied for a total of 3,405 German and international patents. Nearly 41 per cent of their recent revenues came from new products and innovations, which they brought to the market before their competitors (average of all SMEs in Germany: 6.6 per cent). This success is no accident: the top innovators invest an average of 10.5 per cent of revenues in research and development (average of all SMEs in Germany: 1.5 per cent). Two thirds of the Top 100 are family businesses.

The Top 100 competition

Since 1993, compamedia has been awarding the Top 100 seal of approval to SMEs with particular innovative capacity and above-average success rates for innovations. This project has been coordinated by Professor Nikolaus Franke from the Institute of Entrepreneurship and Innovation at the Vienna University of Economics and Business Administration since 2002. Professor Franke is one of the world’s leading experts in the field of user innovation. The Top 100 is mentored by journalist and television presenter Ranga Yogeshwar, and organised in partnership with the Fraunhofer Society for the Promotion of Applied Research. manager magazin provides media support for the company benchmarking competition. Further information is available at www.top100.de.

compamedia – mentor to Germany’s top SMEs

compamedia GmbH, which was founded in 1993 and employs 15 people, organises the nationwide company benchmarking competitions Top 100 (since 1993) and Top Consultant (since 2010). The company collaborates with prestigious universities on these projects.

02.2014

Rankings For The Best of Industries Award 2013

Ernst Blissenbach GmbH has received the coveted award “Best of IP 2013” for the second time.

The publishing house Huber Verlag für Neue Medien is handing out the INDUSTRIEPREIS for the eighth time to honor the best solutions in industry. This award is presented to the most innovative product developments and market launches by industrial companies, suppliers and service providers. All entries are evaluated by an expert panel consisting of professors, scientists, trade journalists and industry experts on the basis of established criteria like innovative strength or product benefit. Ernst Blissenbach GmbH successfully qualified again and received the coveted “Best of IP 2013” award for their welding seam monitoring.

There are many reasons for the global market leader's success. Some are based on concrete facts: Ernst Blissenbach GmbH started introducing innovations for the tube manufacturing industry more than 30 years ago. That also means: Blissenbach customers can save huge amounts on a monthly basis by adding the lastest development – welding seam monitoring - to their eb inside tube scarfing systems.

Ideas are endlessly put to the test

At Ernst Blissenbach GmbH constant development is not one goal among others, rather it is the condition for survival in a high technology field. For the manufacturer of complete inside tube scarfing systems proximity to the market is essential starting with the first step. That is also the reason why their innovation marketing is based on intensive cooperation with the customer. Management puts every idea through numerous tests before it is allowed to enter the market as yet another innovation - and so far they have been extremely successful at that.

This company based in Remscheid is an international market leader when it comes to process solutions for “inside tube scarfing systems for the removal of the internal weld in HF longitudinally welded tubes” – even if the average consumer does not really know how valuable that is for him. Even though we all encounter the indirect results of the intelligent technologies of the Ernst Blissenbach GmbH on a daily basis without being aware of it. In our cars for example, which contain up to 80 m of tubes that have undergone inside scarfing with the help of eb custom tools - a very important precondition for further processing of the tube. For us consumers - that means that we have peace of mind, which is very important to us.

Market proximity through exchange of information

In order to maintain the global leadership position and to be able to address market needs without delays the development department is located at the core of the company. Customer facing departments like Service and Support are engaged in a continuous exchange with engineering. The key benefit of this model is that any employee can provide the impetus for a new project. Consistent proximity to the market is the objective of this cooperation. That also explains why the founder and owner of the company Ernst Blissenbach alone is spending three quarters of his time on innovation every day.

01.2011

The Seal of Approval IP 2011: Honoring the Best.

Ernst Blissenbach GmbH Among the Top Ten.

In April the Huber Verlag für Neue Medien (Huber Publishing House for New Media) for the sixth time awarded the INDUSTRIEPREIS to the best industry solutions. This years' awards were presented under the auspices of the DTAD – Deutscher Auftragsdienst. Recipients were chosen for the most innovative product developments and market innovations in industrial, subcontractor and services companies. An expert group consisting of university professors, scientists, industry journalists as well as experts from different industries evaluated submissions of more than 500 nominated companies on the basis of a set of criteria like innovative content and product benefit. Ernst Blissenbach GmbH successfully qualified and placed among the top ten in the production technology category.

There are many reasons for the world market leaders` success. Some of the reasons are concrete facts: Ernst Blissenbach GmbH holds numerous international patents and started introducing innovations for the tubing industry more than three decades ago. That also means that Blissenbach customers can achieve enormous savings every month by upgrading their eb ID scarfing system with the latest innovation – “Weld Monitoring”.

Ideas Undergoing Numerous Tests

At Ernst Blissenbach GmbH continuous development is not one objective among many, but rather a basic requirement for survival in a high-tech environment. Being close to the market right from the start is a must for a manufacturer of complete ID scarfing systems. That is why intensive cooperation with the customer is the focal point of innovation marketing. The management of Ernst Blissenbach GmbH subjects every new idea to a myriad of tests before it is allowed to conquer the market as the next innovation - and it always does so with great success.

This company from Remscheid is the international leader when it comes to providing process solutions for "Tube ID scarfing systems of premium quality for the removal of the weld bead in high-frequency, longitudinally welded tubes“ – even if the average consumer has no idea, how valuable that is for him. Each and every one of us, indirectly and without realizing it, comes face to face with the technology of Ernst Blissenbach GmbH. A car for example can contain 80 meters or more of tubes that had their inside welding bead removed by premium tools supplied by eb – which constitutes a major precondition for the further processing of the tubes. That gives consumers like us the all-important and reassuring “good feeling”.

Market Proximity Through Exchange of Information

In order to keep its world-wide leadership position and to be able to offer tailor-made solutions the development department has been moved to the center of the company. Customer-facing areas like Service and Support are engaged in a constant exchange with the engineers. What is really special about this model is the fact that any of the employees can initiate a new project. Consistent proximity to the market is the goal of this cooperation. It is not surprising that Ernst Blissenbach, the founder and owner of the company, spends three quarters of his time on innovations.

Downloads

Product folder as e-paper to leaf through

(New page with direct view)

Product folder as PDF

(Download as PDF file)

Inquiry form as PDF

(Download as PDF file)

In order to be able to read our PDF-downloads you need Adobe Reader which can be downloaded here: get.adobe.com/de/reader/

Site Notice

Information pursuant § 5 German Telemedia Act (TMG):

Ernst Blissenbach GmbH

Complete Systems for Inside Tube Scarfing

An der Hasenjagd 8

42897 Remscheid

Germany

Represented by: Ernst Blissenbach

Kontakt:

Telephone: +49 2191 9982-0

Fax: +49 2191 9982-24

E-Mail: info@blissenbach.de

Register Entry:

Entry in the commercial register.

Court of registration: Local Court of Wuppertal

Registry number: HRB 11914

VAT Identification Number:

VAT identification number in accordance with §27 a German Value Added Tax Act:

DE 812249785

Information on Professional Liability Insurance:

Name and location of the insurer:

Berufsgenossenschaft Holz und Metall

Kreuzstraße 45

40210 Düsseldorf

Germany

Insurance Coverage: Wordwide

Responsible for the Content in Accordance with § 55 para. 2 of the German Interstate Broadcasting Treaty (RStV):

Arnd Blissenbach

Disclaimer

Source: eRecht24

Content Liability

As service provider, according to § 7 paragraph 1 of TMG, we are responsible for the content on this site under the general law. Pursuant to §§ 8 through 10 TMG, however, we as service providers are not responsible for monitoring transferred or stored information of third parties or for researching circumstances that suggest an illegal activity.

Obligations for the removal or barring of the use of information in accordance with legal regulations remain unaffected, even in the event of the service provider not being responsible. Any liability in this respect is, however, only incurred from the moment that knowledge of the specific breach of law is obtained. When infringements, such as this, come to light, the relevant content will be removed forthwith.

Liability for Links

Our site contains links to external websites of third parties on which we have no influence at all. We can therefore also not assume liability for these external contents. It is the respective provider or operator of the websites who is responsible for the content of these pages. The linked pages were checked for any legal irregularities at the time of the establishment of the link and no illegal contents were recognisable at that point in time.

However, permanent checking of the linked pages in terms of content is not reasonable without specific evidence indicating illegal activities. We will immediately remove such content upon discovery of infringements.

Copyright

The content and works provided by the operators of these web pages are governed by the copyright laws of the Federal Republic of Germany. The reproduction, adaptation, dissemination or any kind of utilisation outside the borders of copyright law, require the written consent of the respective author or creator. These pages may only be downloaded and copied for private use.

Insofar as the contents of this page was not compiled by the operator, the copyrights of third parties are respected. Contributions by third parties are identified as such. If you nevertheless become aware of an infringement of copyright, we request immediate notification. As soon as we become aware of any infringements of the law we shall remove the corresponding content immediately.

Privacy Policy

Source: eRecht24

Data Protection

The operators of these web pages take the protection of your personal data very seriously. We treat your personal data with confidentiality and in accordance with applicable privacy legislation, as well as this privacy policy.

Generally, the use of our website is possible without providing personal information. To the extent that personal data (name, address, email address etc.) are requested, providing such information is, as far as possible, optional. No personal data will be forwarded to any third parties without your express consent.

We would like to point out that the transfer of data on the internet (e.g. during communication by e-mail) may have security gaps. It is not possible to protect such data completely against access by third parties.

Privacy Policy for the Use of Google Analytics

This Website utilizes features of the web analytics service provider Google Analytics. The provider is Google Inc., 1600 Amphitheatre Parkway Mountain View, CA 94043, USA.

Google Analytics uses so-called "Cookies". These are text files, which are saved on your computer to enable an analysis of your use of the website. The information collected by the cookie from your use of the website is generally transferred to a server in the United States and saved there.

For more information on Google Analytics` handling of user data please visit the Google privacy policy: https://support.google.com/analytics/answer/6004245?hl=de

Browser Plugin

You may refuse the use of cookies by selecting the appropriate settings on your browser, however please note that if you do this, you may not be able to use the full functionality of this website. You can also prevent the collection and transfer of the data generated by the cookie relating to your use of the website (incl. your IP address) to Google as well as the processing of this data by clicking on this link and downloading and installing the browser plugin available: https://tools.google.com/dlpage/gaoptout?hl=de

Objection to Data Collection

You can prevent the collection of your data by Google Analytics by clicking on the following link. An opt-out cookie is set, which will prevent the collection of your data during future visits to this website: Deactivate Google Analytics

IP Anonymisation

On this website we utilize the function "Activation of IP Anonymisation". By doing this, your IP address will be shortened by Google beforehand if you are located within the member states of the European Union or in other parties to the Agreement on the European Economic Area. Only in exceptional cases will the full IP address be transferred to a Google server in the US to be shortened there. Under the authority of the provider, Google will use this information in order to evaluate your use of the website, to create reports on web activity and to provide additional services to the operator of the website relating to the use of the website and the internet. The IP address transferred from your browser to Google Analytics will not be combined with any other Google data.

Privacy Policy for the Use of Google+

Our website utilizes features of Google+. The provider is Google Inc., 1600 Amphitheatre Parkway Mountain View, CA 94043, USA.

Collection and disclosure of information: Using the Google+ button you can publish information worldwide. The Google+ button also provides you and other users with personalized contents from Google and our partners. Google saves both the information, that you entered +1 for a content as well as information on the page you looked at when clicking on +1. Your +1 can be displayed as notes together with your profile name and your photo in Google services, such as in search results or in your Google profile, or in other places on websites and ads on the internet.

Google records information on your +1 activities in order to improve Google services for you and others. For you to be able to use the Google+ button you need a public Google profile that is visible worldwide and contains at least the name chosen for the profile. That is the name used in all Google services. In some instances this name can also replace another name that you used to share content via your Google account. The identity of your Google profile may be seen by users who know your email address or other identifying information on you.

Use of the information collected: In addition to the uses described above the information you supply will also be used according to the current Google privacy policy. Google may publish aggregated statistics on the +1 activities of users or share them with users and partners like publishers, advertisers or affiliated web sites.

Privacy Policy for the Use of YouTube

Our website uses Plugins of the Google operated site YouTube. The provider of the website is YouTube, LLC, 901 Cherry Ave., San Bruno, CA 94066, USA. If you visit one of our website pages equipped with a YouTube plugin, a connection to the YouTube servers will be created. When that happens, the YouTube server will be told which ones of our pages you have visited.

If you are logged into your YouTube account, you enable YouTube to correlate your surfing behavior with your personal profile. You can avoid this by logging out of you YouTube account.

For more information on the handling of user data please visit the YouTube privacy policy under: https://www.google.de/intl/de/policies/privacy

Information, Deletion, Blocking

At any given time you have the right to consult, free of charge, your personal information recorded by us (including the origin of this data, the recipient and the purpose of the data processing), as well as having the right to correct, block, or delete all of this data. If you have any questions about this or the topic of personal data you can contact us at any time under the address listed in the site notice.

Contact Form

When you send us requests using the contact forms, we will save the information from the form, including the contact data entered, in order to process the request and in case of additional questions in the future. We will not share this data without your permission.

Objection to Promotional Emails

The use of contact data published to fulfill the legal requirements of a site notice by a third party for the consignment of advertisements and information, which was not specifically ordered, is hereby explicitly objected to. The operator of this site expressly reserves the right to legal action in the event of unsolicited advertisements, possibly via spam emails.

Sitemap

BLISSart Products

– Process Engineering

– ID Scarfing Systems

– Suspension

– Tube Penetration

– Impeder for Mechanical ID Scarfers

– Impeder for Hydraulic ID Scarfers

– Impeder with Safe Coat System

– Mechanical ID Scarfers

– Mechanical ID Scarfers with Integrated Notching Wheel

– Hydraulic ID Scarfers

– Cutting Ring Cooling Mechanical Hydraulic

– External Cutting Ring Height Adjustment

– Cutting Rings

– Filter

– Ferrite

News

– New Products

– Trade Show

– Media

Requirements

– Download PDF

– Online Request

– Adobe Acrobat Reader

Site Notice

Privacy Policy

Terms and Conditions

Sitemap